Order your wiring loom now!

DEVELOPMENT

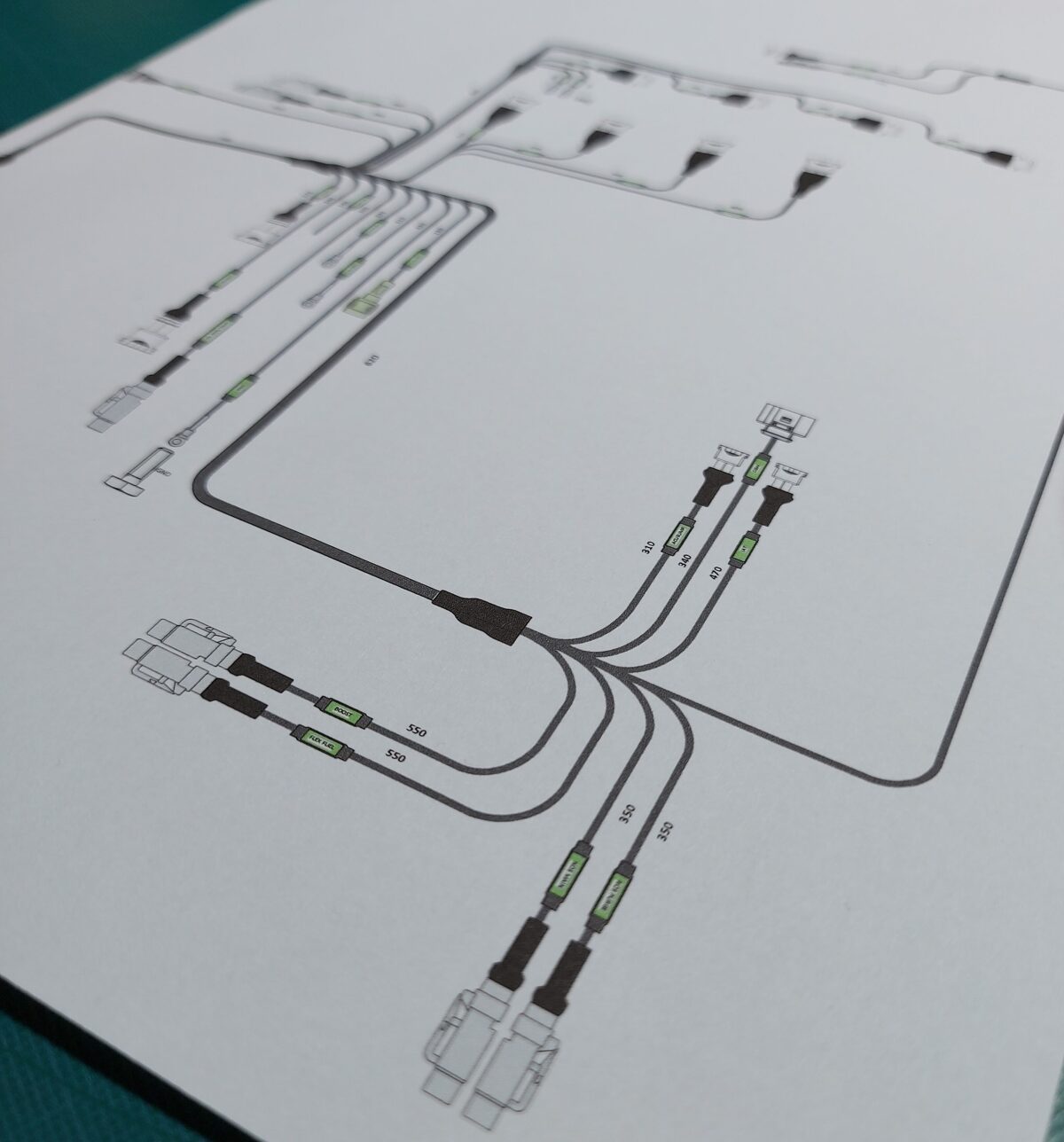

In the development process, the equipment to be installed, sensors, actuators, as well as the materials to be used are selected.

The development stage also includes the creation of a prototype of the overall wiring harness, after which it is possible to make a physical wiring harness.

An important part of the development process is the overall wiring harness layout and pinouts.

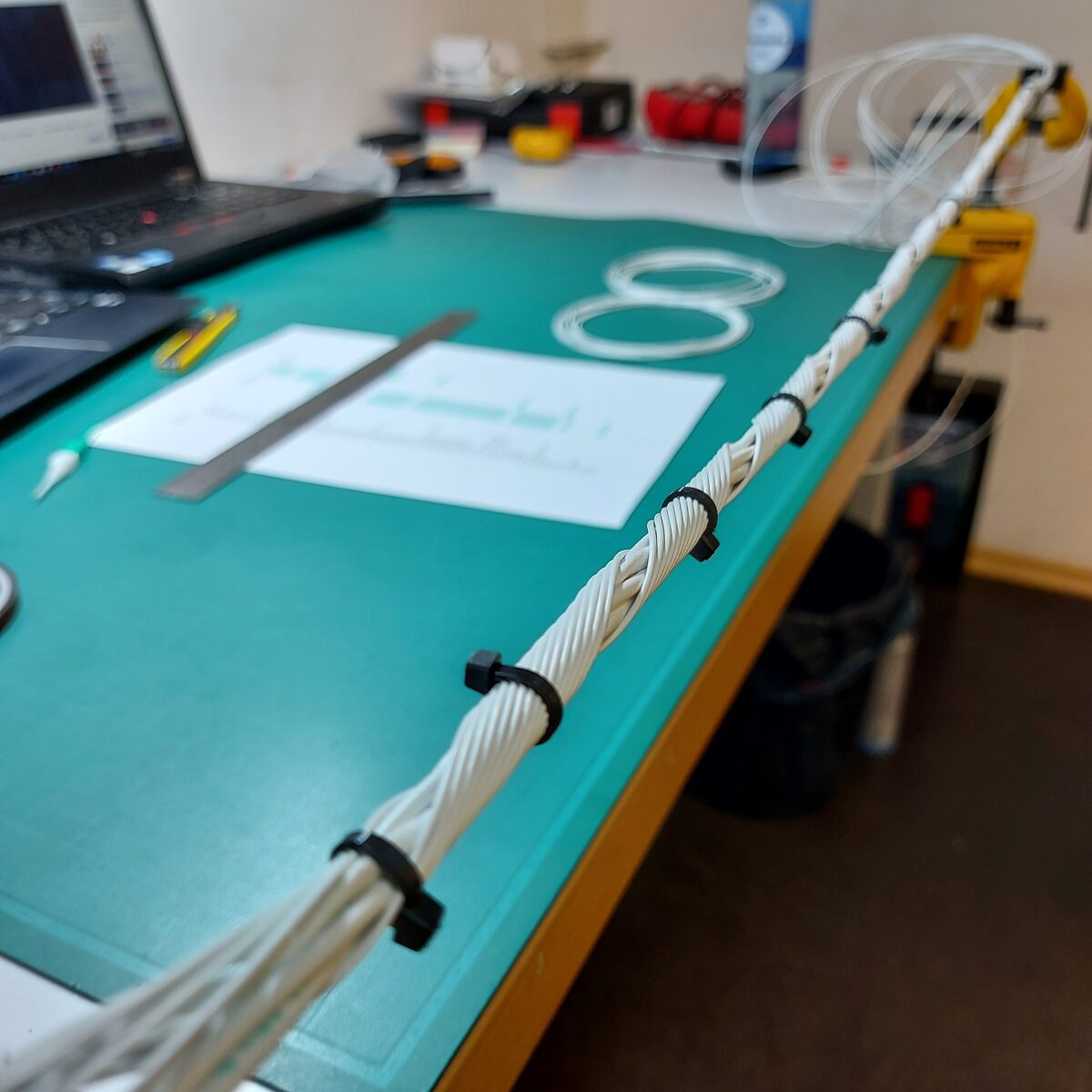

MANUFACTURING

When the wire lengths, layout and circuit termination are clearly known, then the wiring harness manufacturing begins.

The following are used in the production of the wire bundle:

- Tefzel wires

- DR-25 Raychem heat shrinks

- Molded part boots

- Autosport connectors

- RT125 epoxy adhesive

CONNECTOR SEALING

To achieve maximum moisture and dust protection for each connector, if the connector's design allows for it, a molded part boot is applied, and it is sealed using a special flexible, heat-resistant, and chemical-resistant epoxy.

BRANCH POINT SEALING

A professional approach to achieve the highest quality. By carefully sealing the wire connection points, perfect resistance against moisture and dust is achieved.

The epoxy is oil, fuel, and heat resistant.

READY RESULT

This is the result after more than 200 hours of professional-level autosport wiring, which includes:

- Exterior lighting

- Cooling pumps

- Cooling fans

- Fuel pumps

- Interior electronics

- Windshield wipers

- Engine electronics

The quality of materials used ensures the durability of the wire harness in hard conditions, including:

- High thermal resistance in both extreme heat and low temperatures.

- High resistance to external abrasives, sand, dust, mud, etc.

- High resistance to lubricants, fuels, oils, and cooling fluids.

- Elasticity and resistance to vibrations.

- Moisture and water resistance.

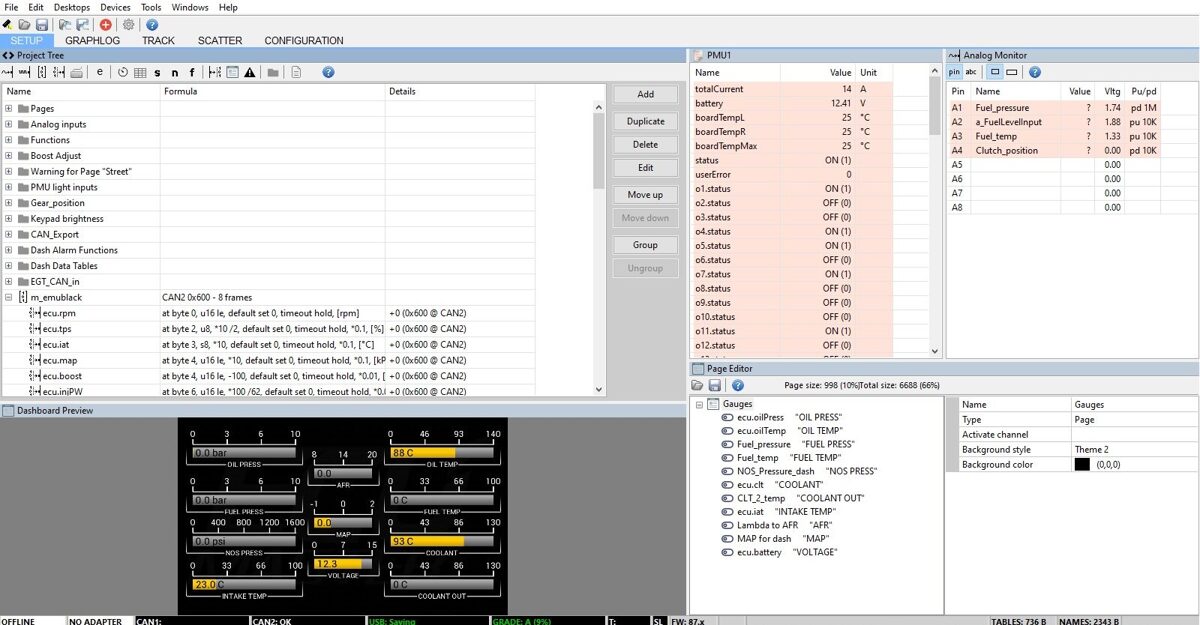

CONFIGURATION

An important stage after the installation of wires is the configuration of the equipment so that all equipment, sensors and actuators are able to function correctly and fulfill the necessary requirements at the required moment.

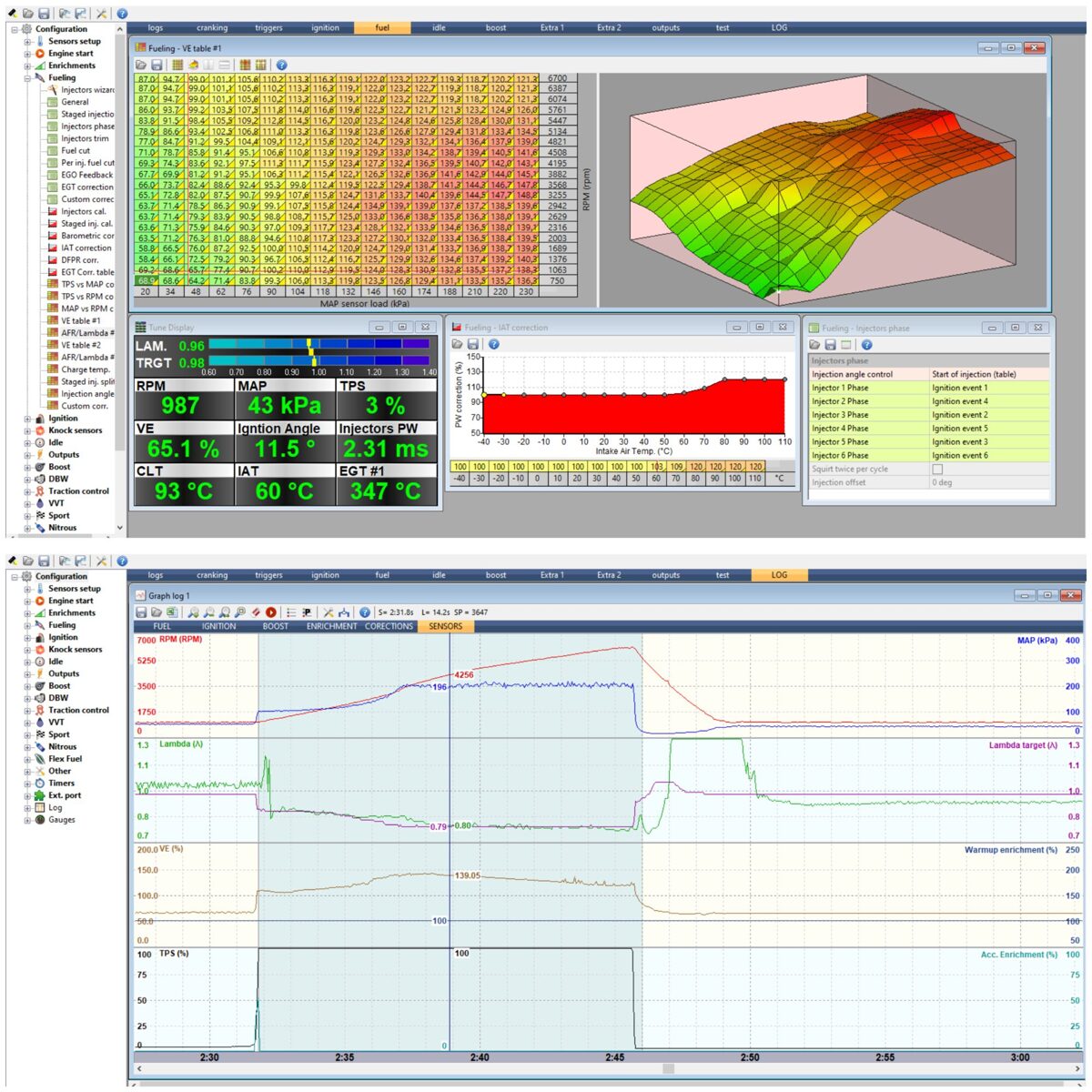

ENGINE CONTROL UNIT TUNING

Finally, in order for the car to be electronically ready to start line, engine control unit tuning is an integral part.

In cooperation with "PDK Chiptuning" it is possible to perform engine tuning to achieve maximum results.